Embarking on the journey of material management requires a solid grasp of the Material Requisition Form. This complete guide, infused with practical examples, walks you through the nuances of effectively using a Requisition Form and Supply Requisition Form. Whether you’re replenishing office supplies or managing large-scale inventory, understanding the intricacies of these forms is essential. Dive into this keyword-rich exploration to enhance your procurement process, ensuring you have the right materials at the right time for seamless operations.

Download Material Requisition Form Bundle

What is Material Requisition Form? – Meaning

A Material Requisition Form is a document used by various departments within an organization to request materials or supplies needed for their operations. It acts as a formal request to the inventory or procurement department, detailing the specifics of the materials required, such as quantity, description, and the purpose of the requisition. This process ensures that resources are allocated efficiently and responsibly, supporting the smooth functioning of organizational activities.

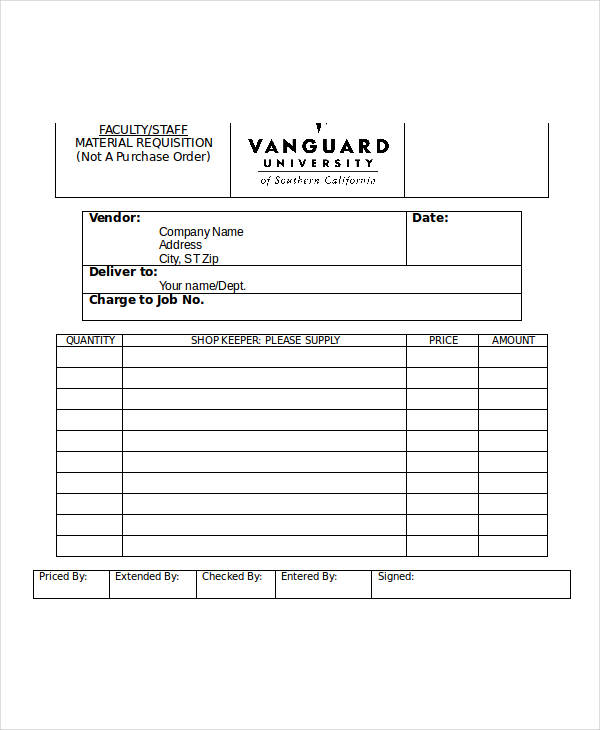

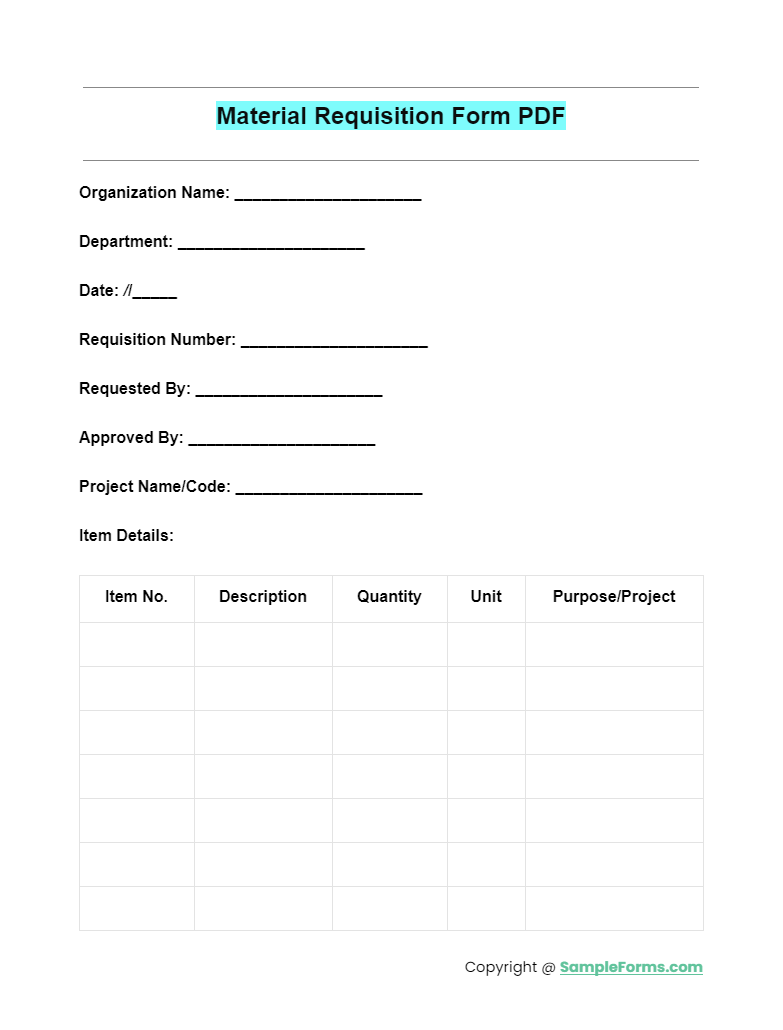

What is the best Sample Material Requisition Form?

This sample form is designed to efficiently handle requests for materials within an organization. It can be customized to fit specific operational needs.

Organization Name: ________________________

Department: _______________________________

Date of Request: ___________________________

Requisition Number: ________________________

Requestor Details

- Name: _______________________________

- Position: ____________________________

- Contact Number: ______________________

Material Details

| Item Number | Description | Quantity | Unit | Purpose/Project |

|---|---|---|---|---|

| (Add more rows as necessary) |

Authorization

- Requested By (Signature): ___________________

- Date: ___________________

- Approved By (Supervisor/Manager): ____________

- Date: ___________________

For Inventory Department Use

- Issued By: _________________________________

- Date Issued: _______________________________

- Comments: __________________________________ (Include any notes on availability, alternatives, etc.)

Instructions:

- Fill out the form with accurate details for each requested item.

- Ensure proper authorization is obtained before submission.

- The Inventory Department should complete their section upon issuing the materials.

Note: This fillable form is a template and can be modified to include additional fields such as budget codes, priority levels, or specific supplier preferences, depending on the organization’s requirements.

Material Requisition Form Format

Material Requisition Form PDF, Word, Google Docs

A Material Requisition Form PDF streamlines the process of requesting materials, ensuring accuracy and traceability. It’s vital for managing Stock Requisition Form submissions, ensuring timely and efficient material allocation.

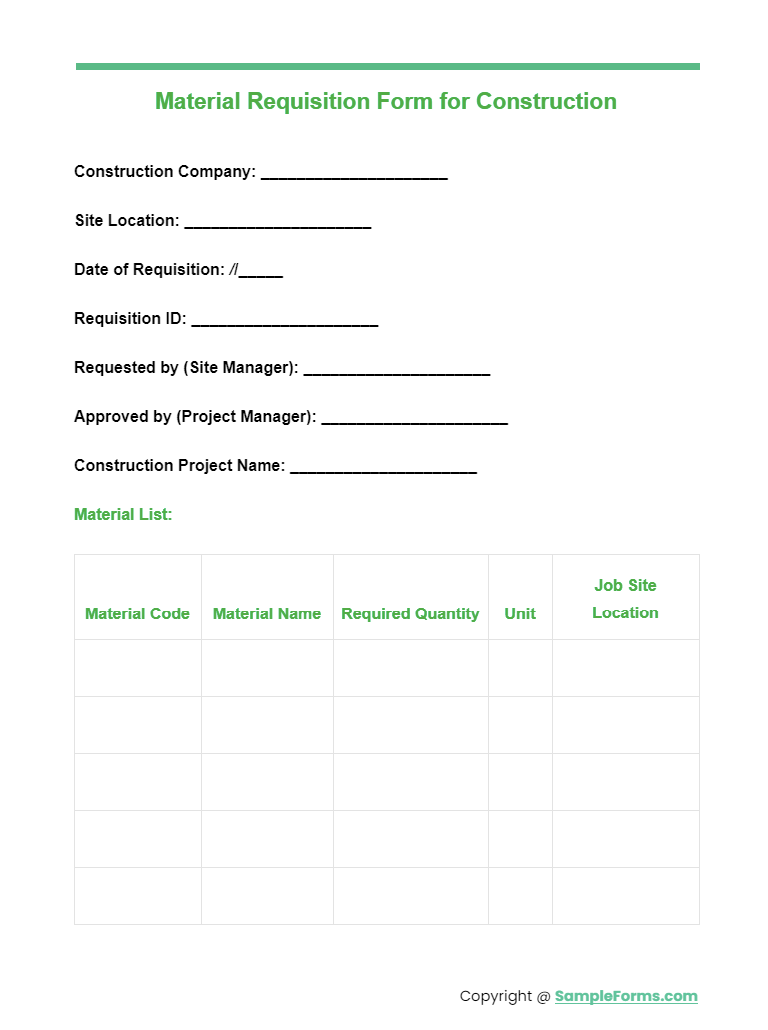

Material Requisition form for Construction

The Material Requisition Form for Construction is crucial for project management, detailing requests for materials like cement and steel. It serves as a Material Transfer Form, ensuring project timelines are met.

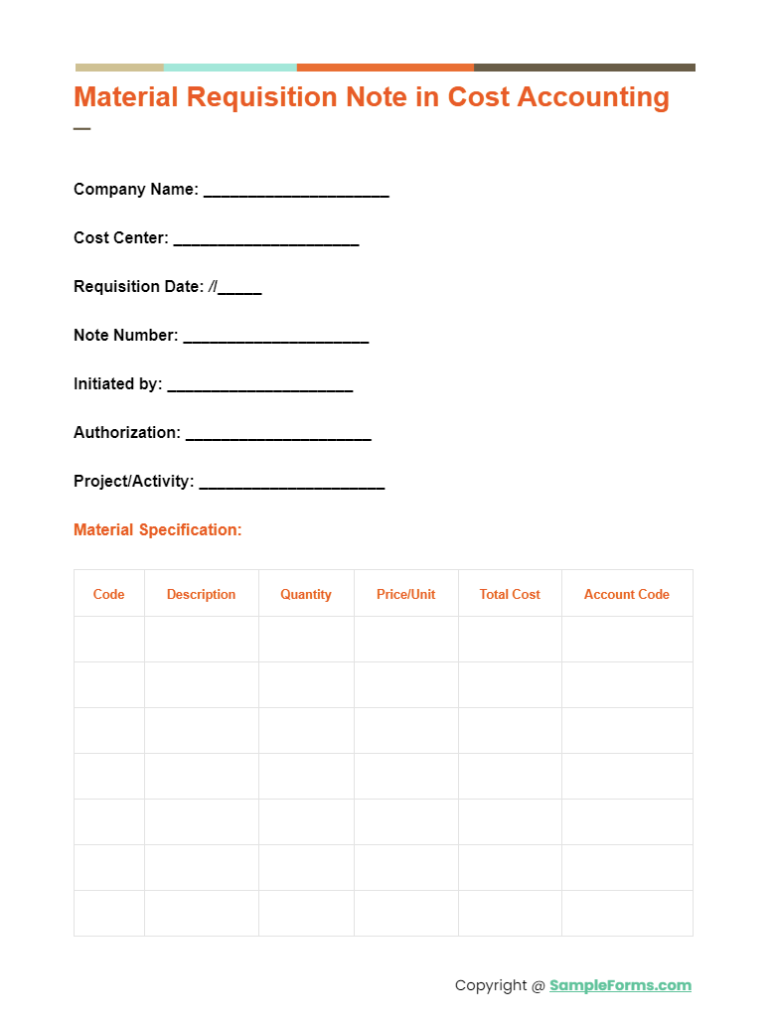

Material Requisition Note in Cost Accounting

In cost accounting, a Material Requisition Note tracks the usage of materials against a budget, crucial for Test Requisition Form processes. It helps in analyzing material costs and budget compliance. You may also check our Requisition Form in DOC

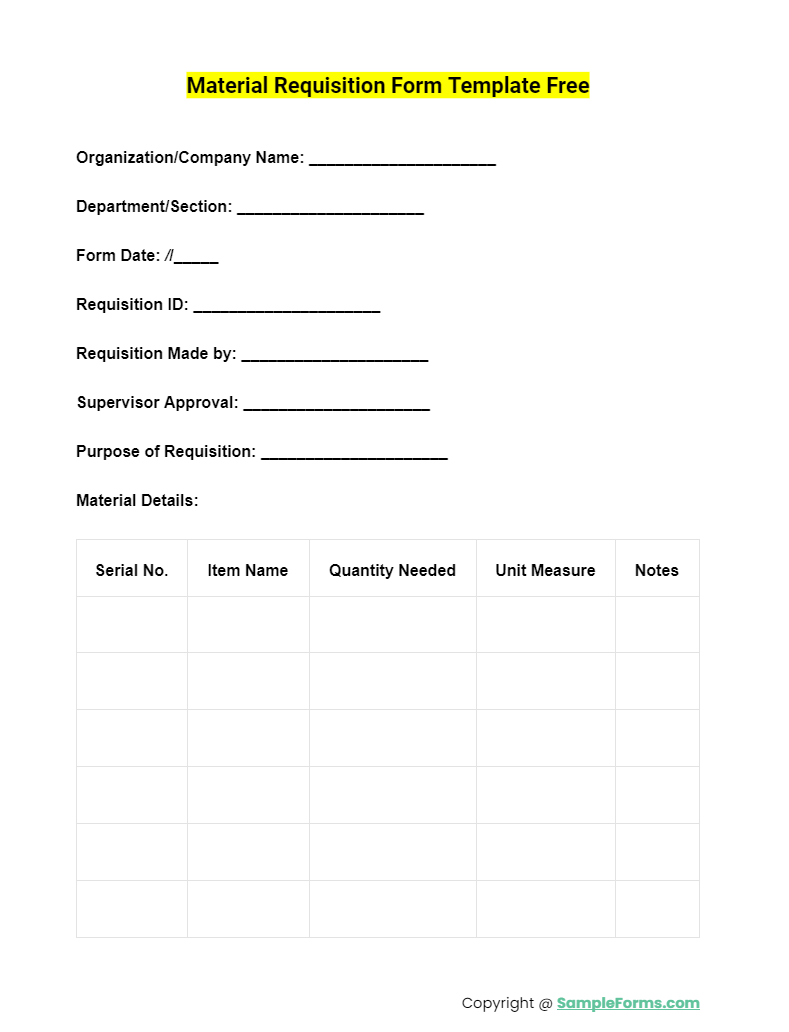

Material Requisition Form Template Free

More Material Requisition Form Samples

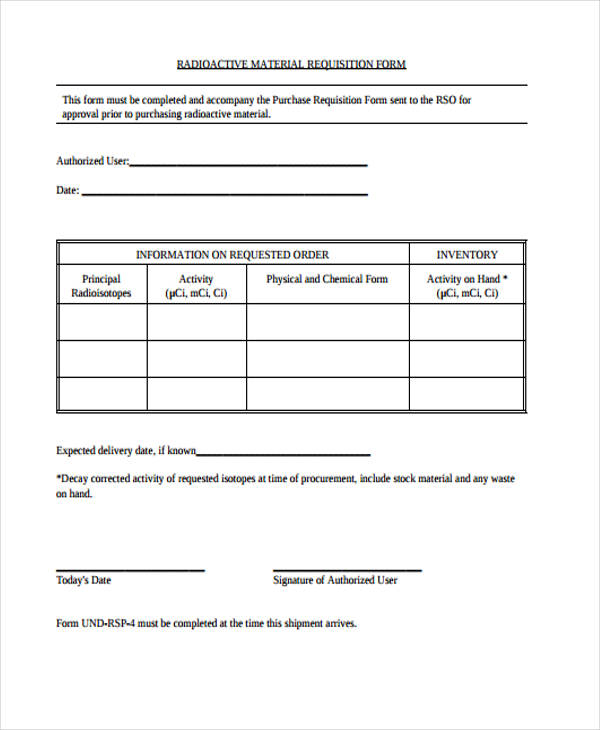

Radioactive Material Requisition Form

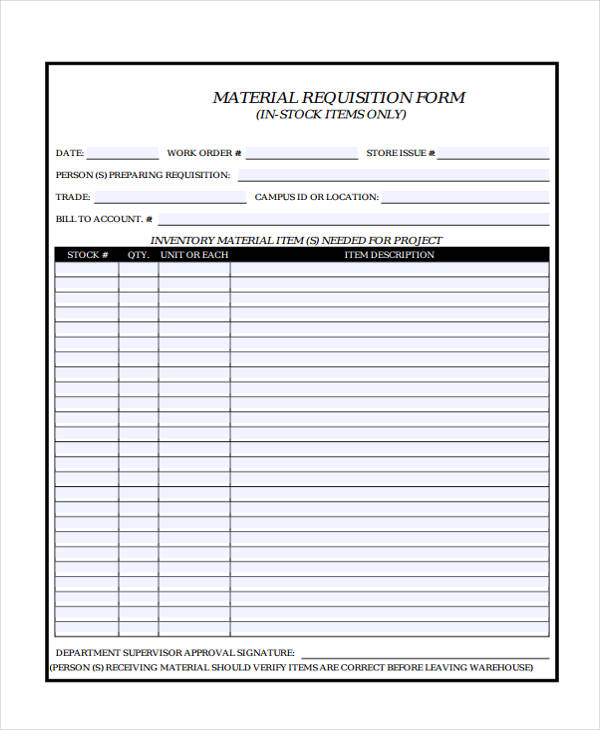

Store Material Requisition Form Example

Material Requisition Form Downloadable

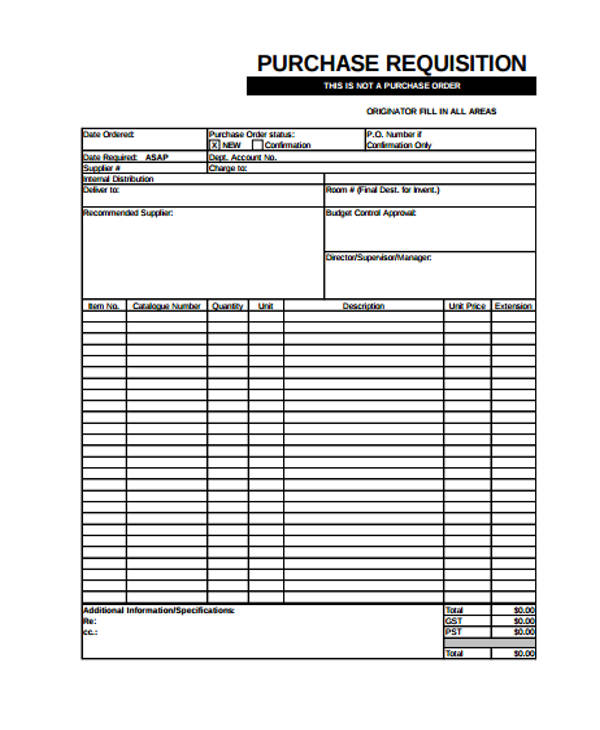

Material Purchase Requisition Form in PDF

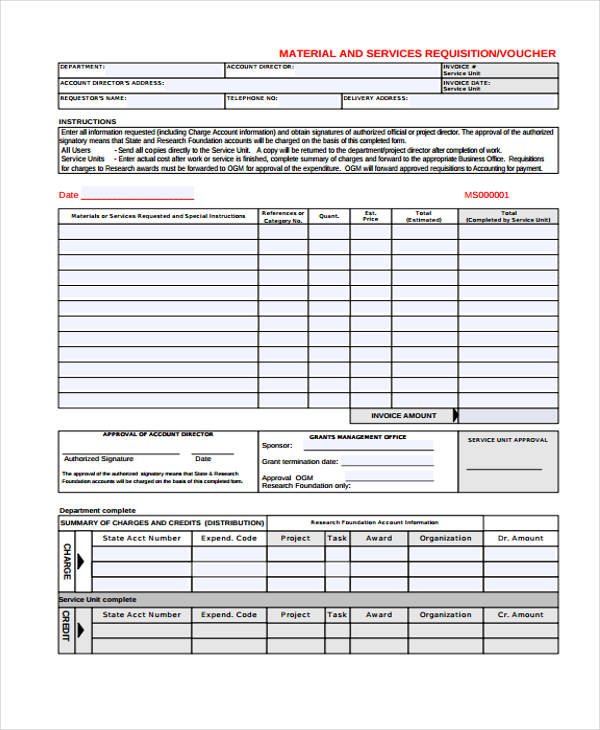

Material Issue Services Requisition Form

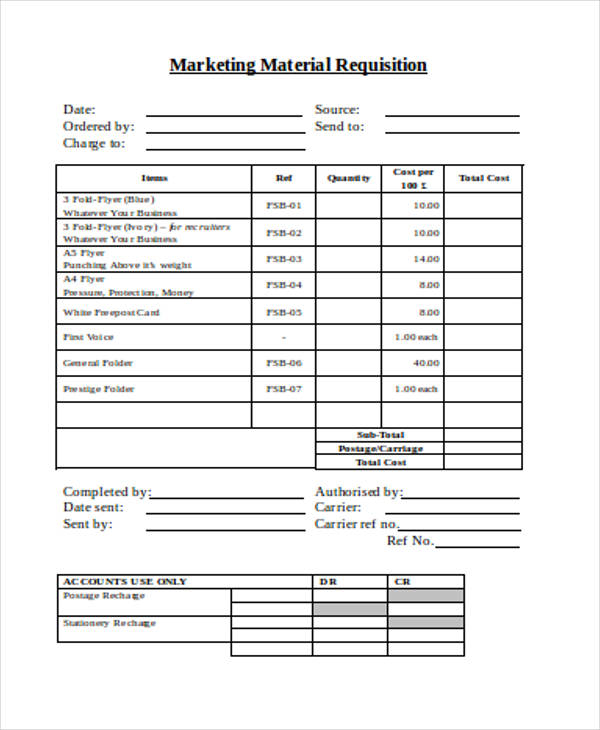

Marketing Material Requisition Form

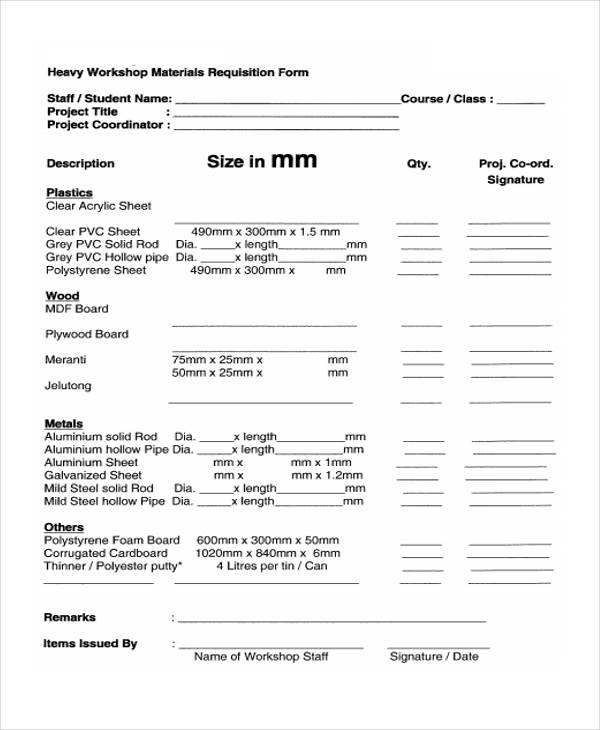

Workshop Materials Requisition Form

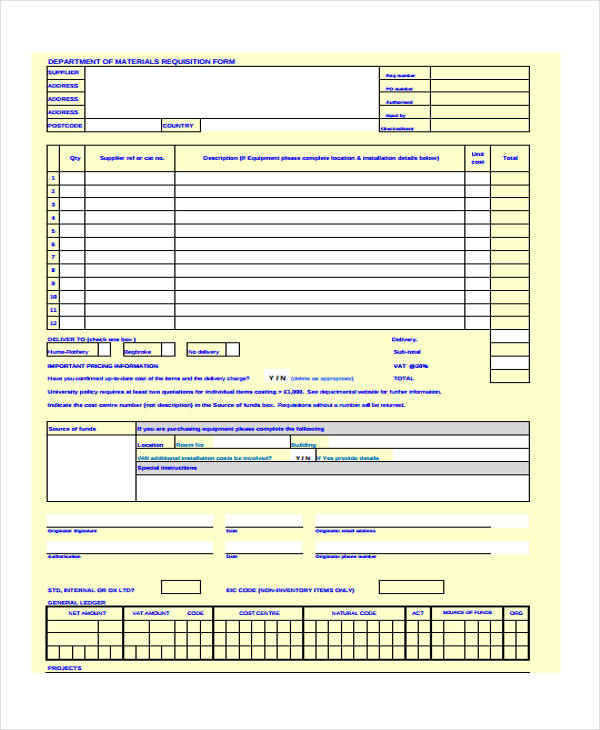

Department of Material Requisition Form

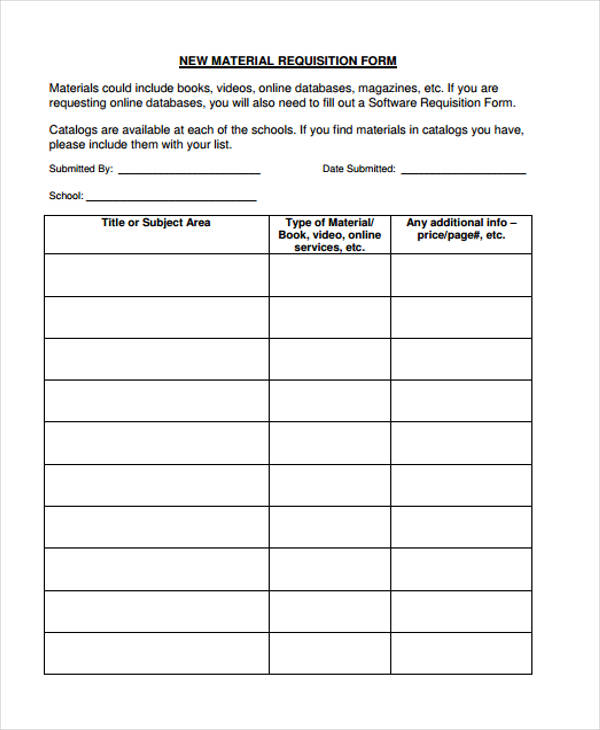

New Material Requisition Form Sample

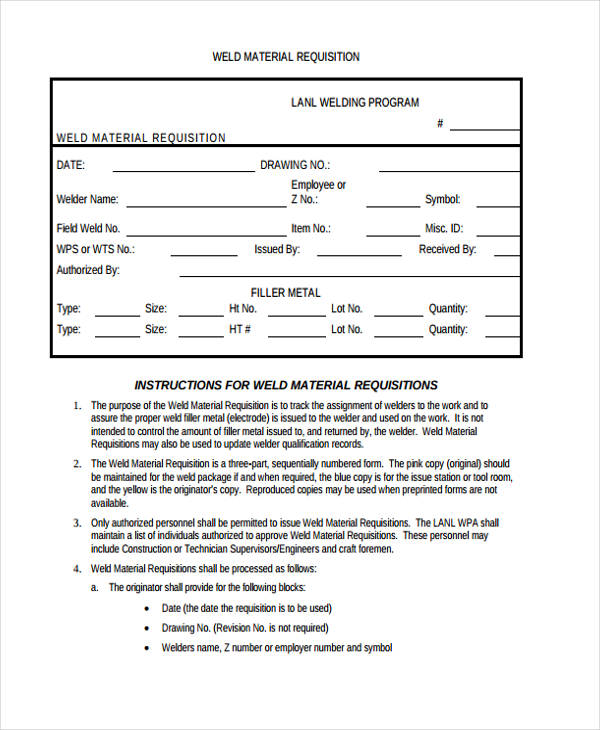

Printable Welding Material Requisition Form

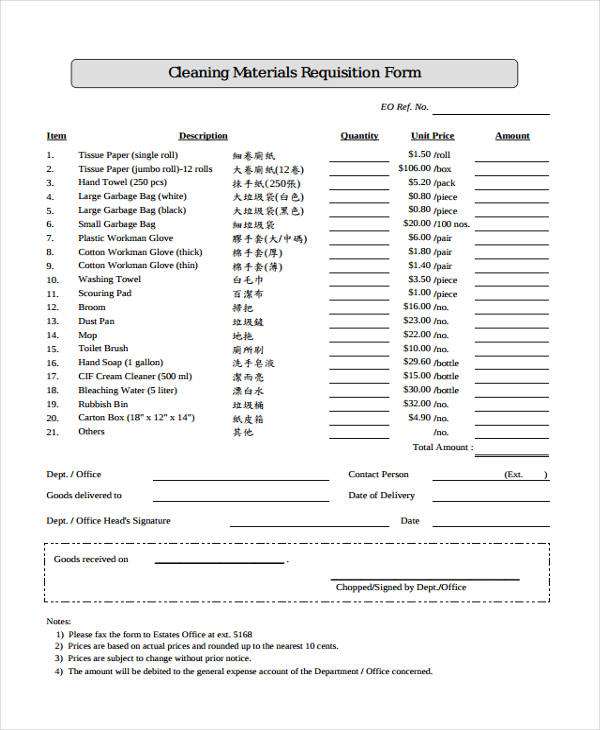

Cleaning Material Requisition Form

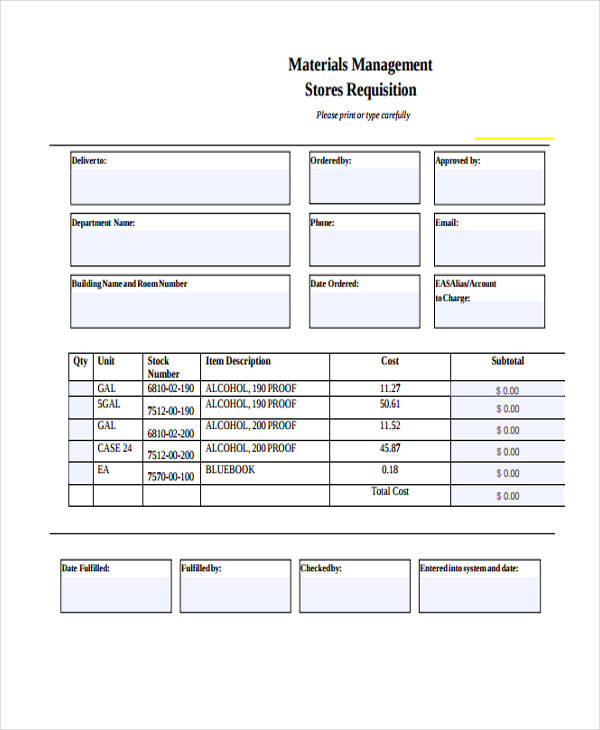

Materials Management Requisition Form

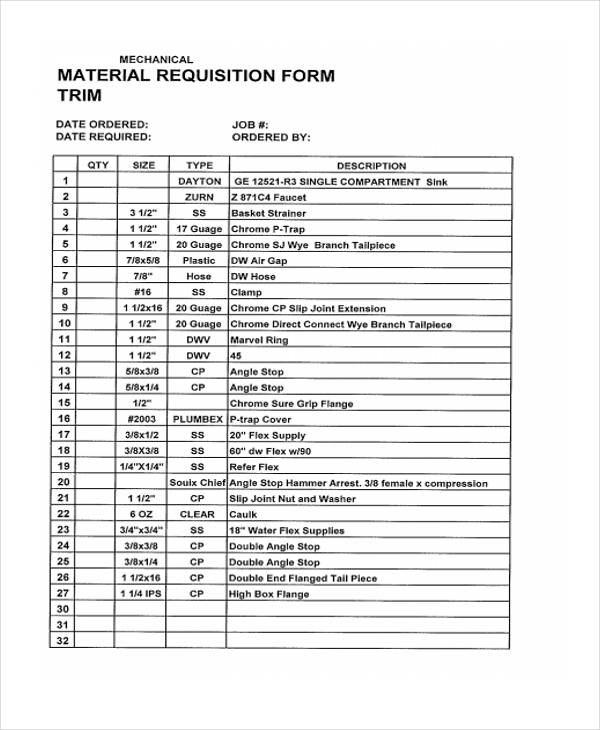

Mechanical Material Requisition Form Format

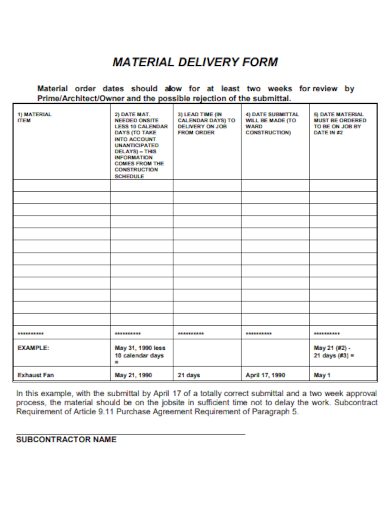

Blank Material Delivery Form

Purchase Order Material Requisition Form in DOC

What is the purpose of a Requisition Form?

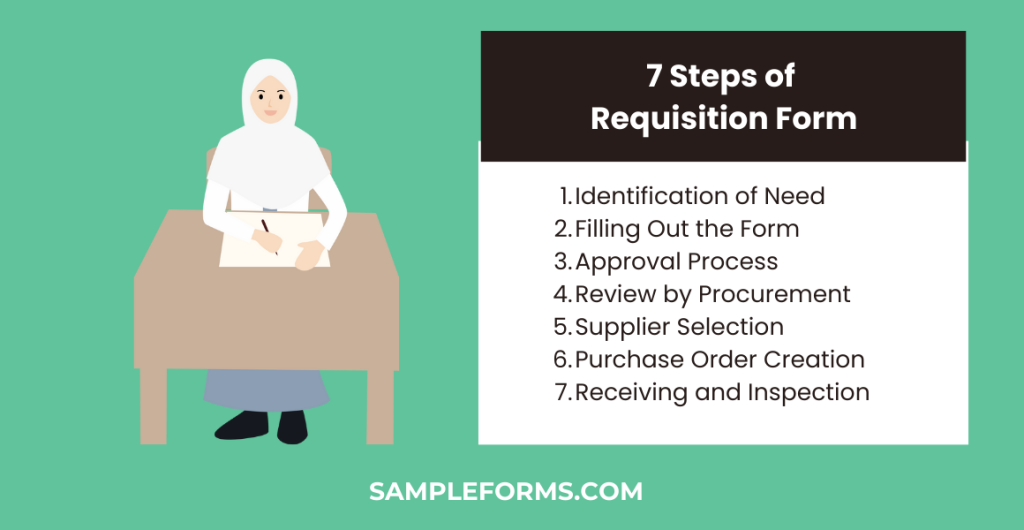

The purpose of a requisition form in an organization is multifaceted, serving as a key tool for efficient operational management. Its primary functions include:

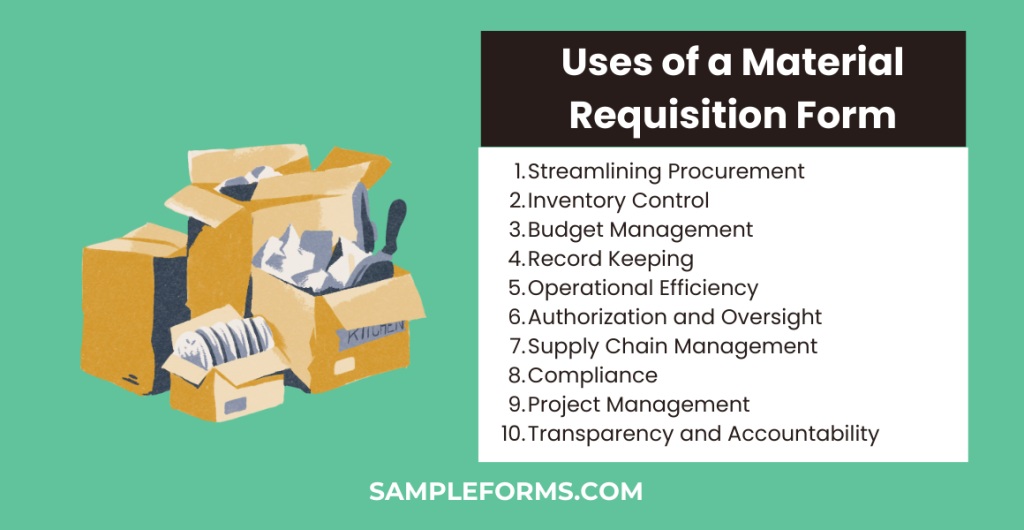

- Formalizing Requests: It provides a formal and standardized method for employees or departments to request goods or services, ensuring clear communication and proper documentation.

- Authorization and Approval: The form typically requires approval from a supervisor or manager, which helps in controlling spending and ensuring that the request aligns with the organization’s needs and budget.

- Inventory Management: In the case of material or supply requisitions, the form aids in tracking inventory levels, helping to maintain adequate stock and prevent shortages or over-ordering.

- Budget Tracking: By documenting requests and approvals, the organization can monitor and manage its budget more effectively, ensuring that expenditures are planned and justified. You may also see Employment Requisition Form.

- Record Keeping: Requisition forms create a paper trail that is essential for accounting, auditing, and historical analysis.

- Efficiency and Timeliness: They streamline the procurement process, ensuring that requests are processed quickly and efficiently, which is crucial for maintaining uninterrupted operations.

- Compliance and Standards: The form can ensure that requests and purchases comply with organizational policies and, in regulated industries, legal standards.

- Project Management: For project-based work, requisition forms help in allocating resources appropriately, ensuring that projects are well-supported and can proceed on schedule.

- Transparency and Accountability: They promote transparency in organizational spending and hold departments accountable for their resource usage.

Overall, a requisition form is a critical component in managing an organization’s resources, facilitating smooth and responsible operations.

Uses of a Material Requisition Form

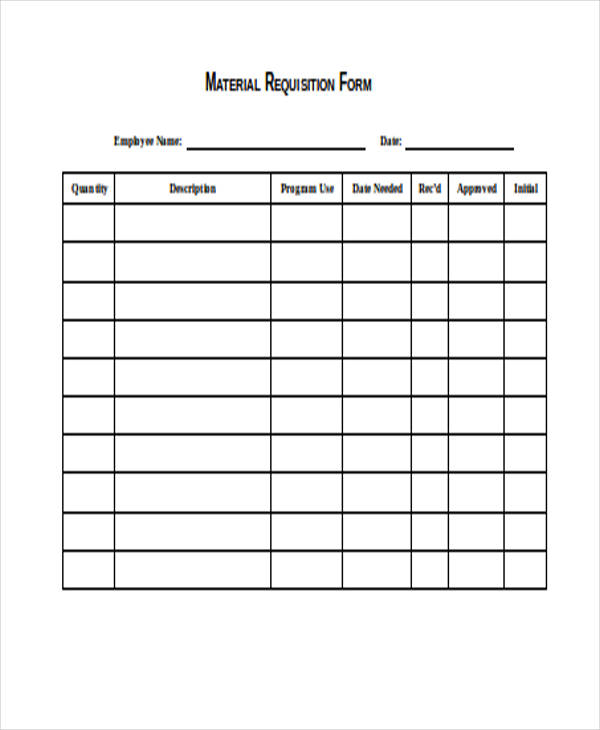

Components of a Material Requisition Form

- The name of the employee and department requesting the materials

- What the materials are for (If it is for a project or job, then the job number should be specified so that the receiving departments will be aware as to who the materials will be charged to.)

- The date the request was placed, along with the date the materials are going to be needed

- A description or item number of the materials requested

- Unit or quantity of materials that have to be pulled from the stock

- The name and signature of the authorized personnel

If the materials have to be delivered, then a delivery address should be included on the Material Requisition Form as well. And if the form will be used as a basis for a service invoice, then the cost of the materials can be included as well so it is easier to calculate the total cost for the service/s provided.

There are various projects for which a Material Requisition Form can be used. You just have to use the right forms that are properly labelled so as to avoid confusion. We also have other Service Requisition Form that are used for other types of requests, not just materials and items needed for a project or service.

When Material Requisition Slip is prepared?

Related Posts

-

FREE 6+ Personnel Requisition Forms in MS Word | PDF

-

FREE 5+ Staff Requisition Forms in MS Word | PDF

-

Employee Requisition Form

-

Payment Requisition Form

-

FREE 8+ Supply Requisition Forms in PDF | Excel

-

FREE 6+ Lab Requisition Forms in PDF | MS Word | Pages

-

Stationery Requisition Form

-

Equipment Requisition Form

-

FREE 10+ Service Requisition Forms in PDF | Ms Word

-

FREE 27+ Requisition Forms in Excel

-

FREE 9+ Employment Requisition Forms in PDF | Excel | MS Word